|

|

Belovac - Made with Pride in USA

|

At Belovac Engineering..

|

|---|

|

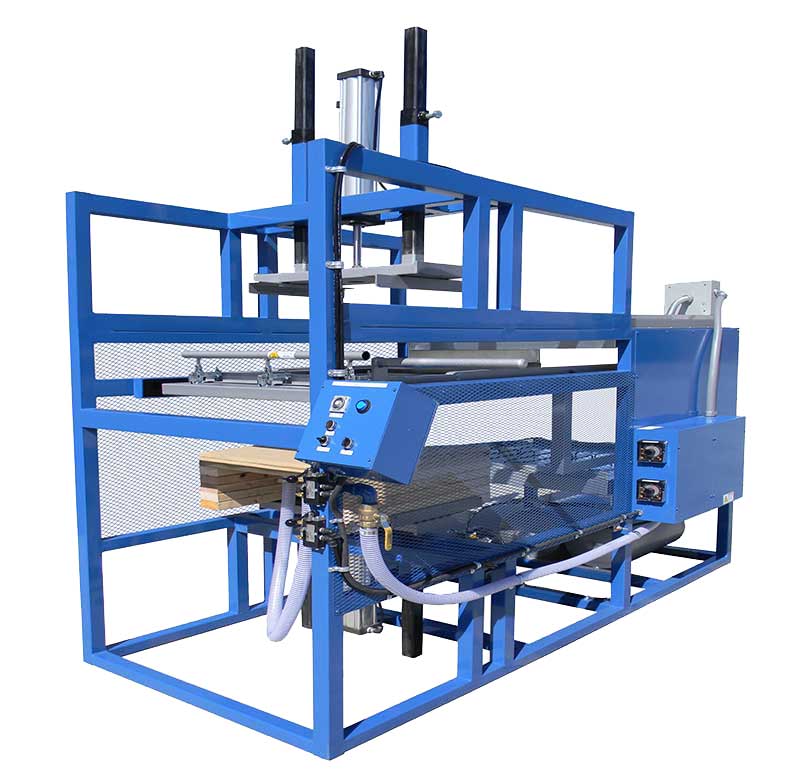

JB 951-741-4822 Manufacturing Pedicure TubsBV-L Class 9' x 20' Former

|

|---|

| At Belovac Engineering.. We offer, time proven, industry-tested vacuum and thermoforming technology. With over 30+ years of designing and developing the most reliable vacuum forming machine in the industry, we would encourage you, our new customer to review our machine options. On this site and on our YouTube station, we have one of the largest libaries of videos of past projects of our real customers. When you contact us.. You'll never speak to a salesperson seeking to earn a commission. You will in fact speak to one of our design engineers. You will be assisted and offered a very clear understanding of the process and the best options for your budget. Please give us an opportunity.. Whether your interest is in one of our standard machine designs or if you face a custom machine dilemma, rest assured we will provide the correct solution. With over 10,000+ satisfied customers world-wide, we provide an alternative to over-built and over-priced equipment. PHONE JB - (951) 741-4822 EMAIL - [email protected] Belovac offers financing on some equipment upon approved credit, inquire about financing today! |

|

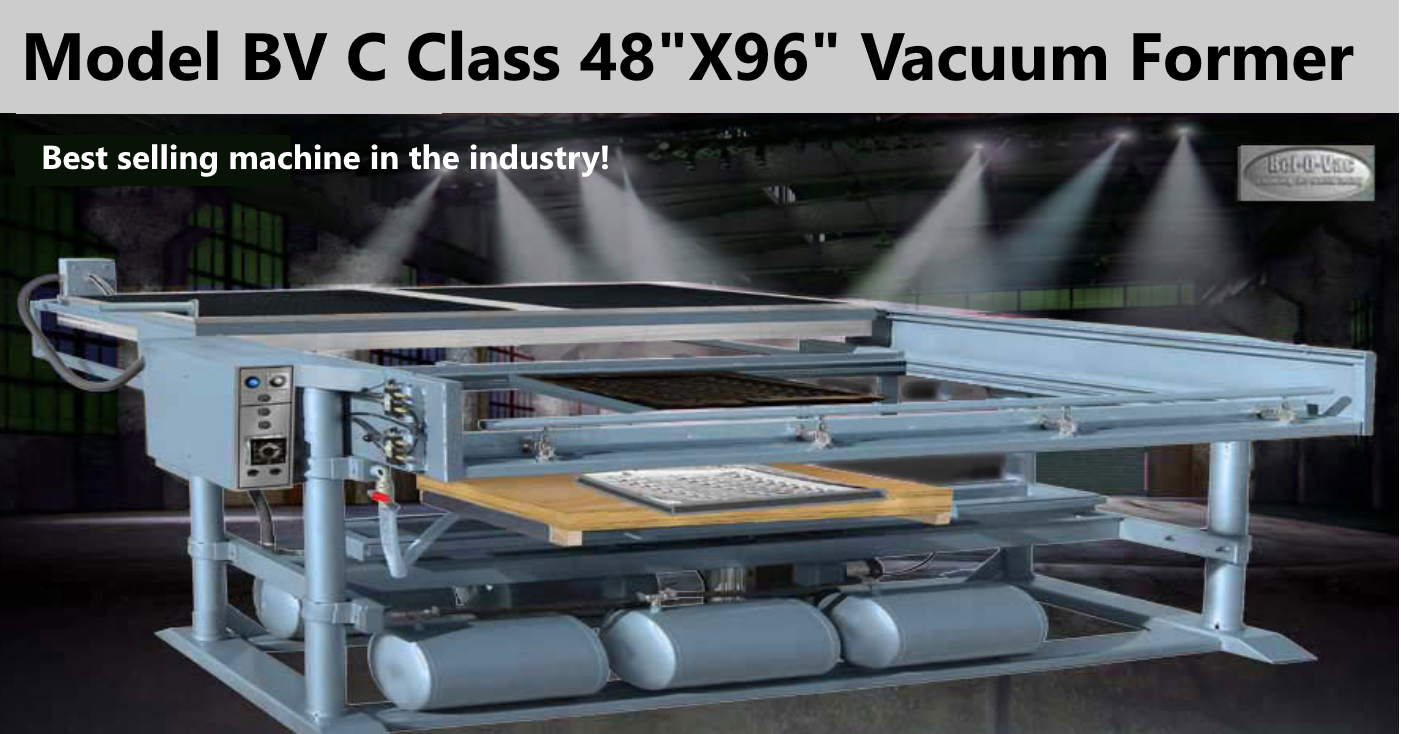

Budgetary Vacuum Forming Machine Modular engineered post and beam thermoformer machine series |

|

Manual Sheet Fed Vacuum Forming Series |

|

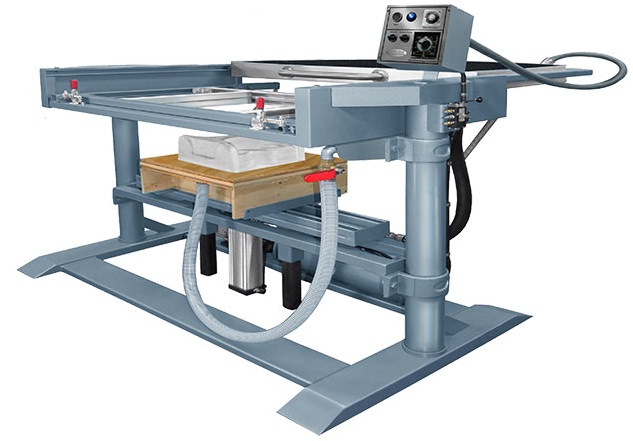

Manual Deep Draw Heavy Gauge Vacuum Forming Machine

53" x 103" (135 x 262cm)

Typically used for the molding of larger structural Components such as- bath

tubs –spas- motor home interiors and exteriors- limo components - auto side

panels- industrial cases-shipping cases –acrylic sky lights- Air plane

interiors – commercial signs- truck linersRecommended plastic gauge

3/8"(.95cm)

thick - ABS / kydex / poly propylene / Acrylic Styrene / PVC

|

|

|

|

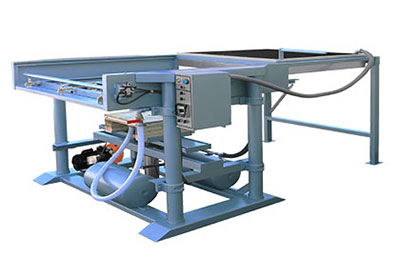

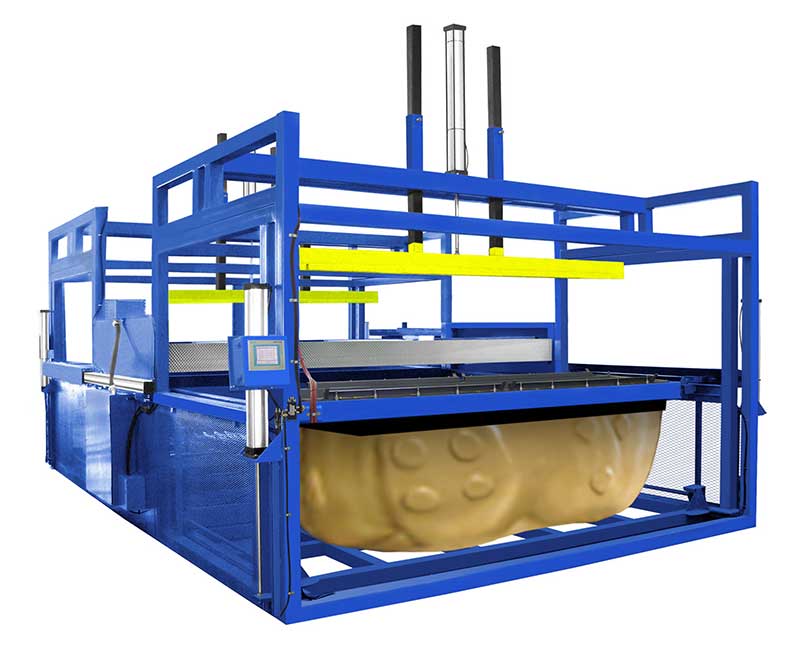

Model BV Dual Station

BV dual station vacuum formers offer hi production with dual tool set ups commonly used

with similar tools were cycle timing is the same, or were two different tool set ups are

required, offering prototyping on one table and production on the opposite table.

Additional advantages equipment requires only one operator for two station production

minimizing on labor cost.

|

|

|

|

|

|

|

|

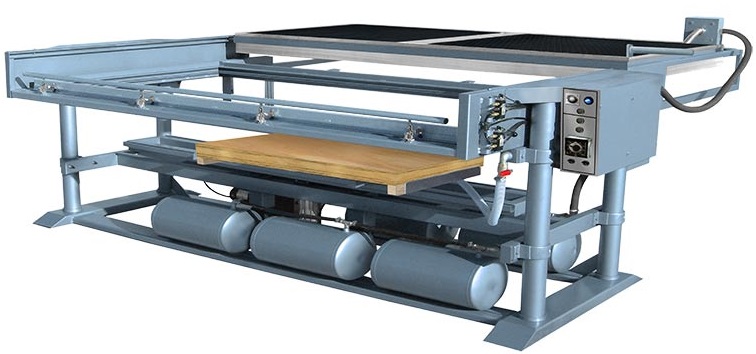

Roll Fed Vacuum Forming Machines

Recommended for the pre-heating and drying of heavy gauge and materials such as

acrylics, polycarbonates, and ABS. This simplistically designed hi-speed Vacuum

Forming

Machine will provide the competitive edge you require to cost effectively

produce

plastic components.

|

|

|

|

|